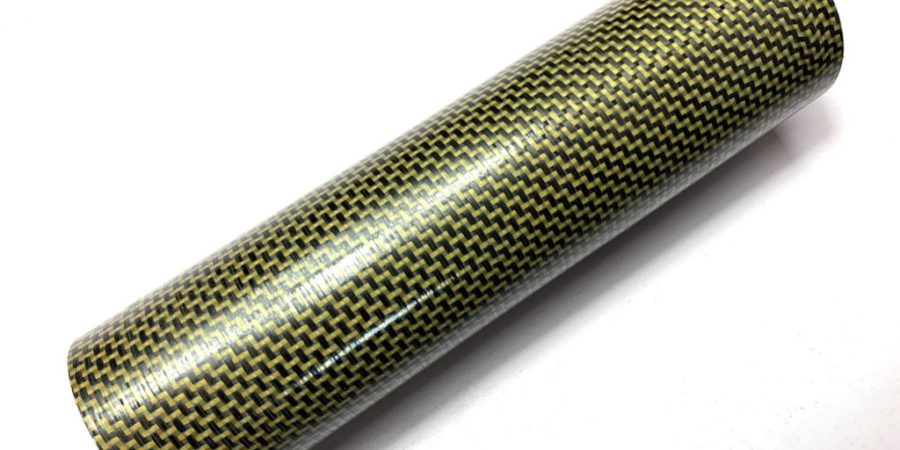

If you replace a 1-m aluminium tube (with a diameter of Ø25 mm, and thickness of 2 mm) with the same tube in carbon fibre and you shed approximately 50% of the weight while gaining more than three times the specific tensile strength. This is a revolutionary advantage in industries where performance per kilogram is top priority.

In aerospace applications, every extra kilogram costs up to about £9,400 to launch into low-Earth orbit. Similarly, in motorsport, a single kilogram of unsprung mass equates to six kilograms of body mass in performance terms. These compelling numbers are the reason why carbon fibre tubes have moved from exotic speciality to mainstream engineering solutions across numerous sectors.

The global carbon fibre market reached roughly £4.5 billion in 2024 and continues to grow at an impressive 10.9% CAGR through to 2030. Carbon fibres are now expanding adoption beyond traditional aerospace and motorsport applications into robotics, medical devices, and even consumer goods.

Let us explore deeper into how carbon fibre tubes‘ remarkable weight and stiffness advantages translate into concrete benefits, from reducing aircraft fuel consumption to extending drone flight times. In the process, let us also explain how Advanced Composite Engineering can help bring these benefits to your next project.

Key Properties of Carbon Fibre Tubes

Understanding what makes carbon fibre tubes special requires looking beyond simple weight reduction. While carbon fibre’s density advantage is impressive, typically half that of aluminium, it’s the combination of lightweight with exceptional mechanical properties that creates true engineering value.

Strength-to-Weight Ratio

Carbon fibre tubes offer a specific tensile strength approximately 3.8 times that of aluminium and 5 times that of steel, while weighing just one-third as much. Hence, a properly designed carbon fibre structure can handle significantly greater loads per unit of weight than metal alternatives.

In practical terms, a carbon fibre tube that weighs 100 grams might replace an aluminium tube weighing 200 grams, yet handle considerably higher tensile forces.

For weight-critical applications like drone arms or satellite components, this property alone can justify the higher material cost through improved performance.

Stiffness-to-Weight Ratio

Equally important is carbon fibre’s specific stiffness, approximately 1.7 times that of aluminium. This translates to less deflection under load, maintaining precision in applications where dimensional stability matters.

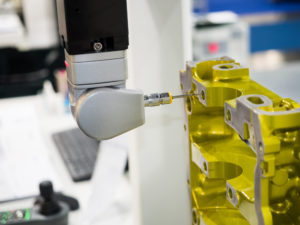

Consider a robotic pick-and-place arm. Reduced flexing and greater positioning accuracy at higher speeds can potentially increase throughput in automated manufacturing.

Near-Zero Thermal Expansion

One of carbon fibre’s most valuable yet often overlooked properties is its extremely low coefficient of thermal expansion (CTE). Carbon fibre tubes can achieve CTE values as low as 0.15 parts per million per Kelvin, compared to 23 parts per million per Kelvin for aluminium.

In practice, imagine a precision measuring instrument with a one-metre beam. As the ambient temperature fluctuates by 10°C:

- An aluminium beam would change length by 230 micrometres

- A carbon fibre beam might change by just 1.5 micrometres

This dimensional stability can make carbon fibre tubes ideal for applications in metrology, scientific instruments, and space systems where temperature swings are common but precision must be maintained.

Fatigue & Corrosion Resistance

Carbon fibre composites typically demonstrate more than twice the fatigue life of aluminium under similar loading conditions. Unlike metals that develop progressive microscopic cracks leading to sudden failure, carbon fibre structures tend to show visible damage well before catastrophic failure occurs, an important safety advantage in critical applications.

Additionally, carbon fibre is immune to galvanic corrosion and shows no degradation in salt-spray tests.

For marine applications, this eliminates the annual maintenance costs associated with stainless steel components, potentially reducing lifecycle costs by up to 30%.

Core Industries & Stand-Out Applications

Carbon fibre tubes have found applications across numerous industries, each leveraging different aspects of the material’s unique property set. Here’s how various sectors are benefiting from carbon fibre technology:

Aerospace & Defence

In aerospace applications, carbon fibre tubes usually serve as satellite booms, antenna masts, and structural elements in unmanned aerial vehicles (UAVs) for defence applications. The economic impact is substantial, with every 10 kg saved trimming launch costs by roughly £94,000.

Advanced Composite Engineering’s roll-wrapped carbon fibre tubes can deliver particular value in space applications through their ability to achieve zero-coefficient thermal configurations.

These thermally stable structures are ideal for optical benches in small satellites, maintaining precise alignment of sensitive instruments despite the extreme temperature variations encountered in orbit.

Motorsport & High-Performance Automotive

Formula 1 teams and high-performance vehicle manufacturers use carbon fibre tubes for torque tubes, rear-wing end-plates, and steering columns.

In motorsport, a fundamental principle holds that 1 kg of unsprung mass (weight not supported by the suspension) is equivalent to 6 kg of body mass in terms of handling performance.

By replacing metal components with carbon fibre alternatives, engineers can achieve sharper turn-in response and faster lap times without making power-train changes. The weight reduction in rotating and reciprocating components also reduces inertia, allowing for faster direction changes and improved acceleration.

Marine & Offshore

Yacht masts, oar shafts, and remotely operated vehicle (ROV) arms represent common marine applications for carbon fibre tubes. As mentioned above, beyond weight savings, the zero-corrosion nature of carbon fibre is particularly valuable in this sector. This reduces the annual maintenance requirements of stainless steel components can cut lifecycle costs by up to 30%, while simultaneously extending service life.

Industrial Automation & Robotics

Carbon fibre tubes excel as components in high-speed pick-and-place arms and vacuum idler rollers in factory automation systems. Carbon grippers are approximately 42% lighter and 30% stiffer than aluminium equivalents, boosting cycle rates by double-digit percentages.

Companies like ABB have demonstrated that carbon fibre booms can handle 100 kg payloads while shortening cycle times compared to metal alternatives. For manufacturers operating high-volume production lines and in industrial applications, these efficiency improvements can translate directly to increased throughput and reduced energy consumption.

Metrology & Scientific Instrumentation

Coordinate measuring machine (CMM) beams and telescope trusses represent precision applications where carbon fibre’s dimensional stability shines. Systems built with carbon fibre can maintain dimensional accuracy within ±1 micrometre per metre per °C across typical laboratory temperature fluctuations.

This exceptional stability eliminates the need for constant temperature control or complex compensation algorithms, simplifying system design while improving measurement reliability.

UAVs, Drones & Space

For commercial drone operators, a 15% frame weight reduction can add 6–8 minutes of flight time to a typical 30-minute mission, a significant operational advantage that can reduce battery changes and increase productive work time.

Likewise, in satellite applications, carbon fibre structures provide the dual benefits of launch weight reduction and on-orbit stability, optimising both deployment costs and operational performance.

Medical & Healthcare Devices

Prosthetic limbs and radiolucent X-ray table supports represent growing applications for carbon fibre tubes in healthcare. Carbon prosthetics reduce limb weight by approximately 35% compared to aluminium alternatives, improving patient comfort and gait symmetry.

For imaging applications, carbon fibre’s transparency to X-rays allows for structures that support patients without interfering with diagnostic quality, eliminating the metal artefacts that can complicate the interpretation of medical images.

Customisation Options For Niche Solutions

While standard carbon fibre tubes offer impressive performance, customised solutions can provide even greater value for specific applications. At Advanced Composite Engineering, we can offer several customisation pathways:

Dimensional Customisation

Advanced Composite Engineering provides carbon fibre tubes with internal diameters ranging from 4.49 mm to 152 mm using standard mandrels, with bespoke solutions available up to 325 mm. Wall thickness can be tailored from ultra-thin 0.6 mm sections to heavy-duty 10+ mm walls, allowing precise optimisation for weight and mechanical requirements.

Specialised Geometries

Advanced Composite Engineering delivers flawless progressive tapers that can be optimised for specific load profiles. Local reinforcements using Kevlar or glass fibre sleeves can strengthen impact-prone zones without adding unnecessary weight to the entire structure.

Surface Treatments

Finish options include matte, high-gloss, peel-ply for secondary bonding, or colour-matched paint to RAL/BS standards. These aesthetic and functional finishes allow carbon fibre tubes to serve in both technical and visible applications without compromise.

Length Options

Standard tubes are available up to 3.6 metres in one piece, with internal splices enabling effectively unlimited length for applications requiring longer continuous sections.

Harness Ultra-Light Performance With Carbon Fire Tubes

Carbon fibre tubes deliver best-in-class weight-to-performance ratios, ultra-low thermal drift and multi-decade fatigue life across an expanding range of applications. Carbon fibre tubes can offer 50% weight reduction compared to aluminium, 3.8 times the specific tensile strength, and thermal stability 150 times better than conventional metals.

This can yield tangible competitive advantages for businesses willing to embrace advanced materials.

Imagine what tailored lay-ups, progressive tapers, or hybrid carbon/Kevlar sleeves could do for your next project. The possibilities extend far beyond simple material substitution to entirely new design approaches that weren’t feasible with traditional materials.

Speak to our Composite Specialist today to discuss roll-wrap carbon, carbon sleeves, or hybrid lay-ups tailored to your specific application requirements.

If you’re new to carbon fibre and composite materials, then our comprehensive composite glossary can provide clear definitions, tolerance expectations, and finish options to help you specify with confidence.

Complete our quick Product Enquiry Form for a quote on custom carbon fibre tubes manufactured to your exact specifications, or get in touch with us to get fast advice on tube sizing, tooling lead-times, and minimum order quantities from our experienced composite specialists.