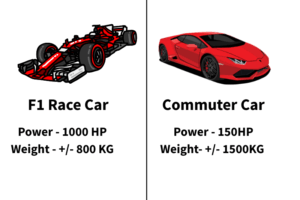

When a Formula 1 team shaves 500 grams from their car’s chassis, they’re not just removing weight. They’re buying fractions of seconds per lap. When a drone manufacturer switches to carbon fibre airframes, they’re simply making their product lighter, whilst doubling flight time and redefining what’s possible in aerospace performance.

This is the essence of weight reduction in performance engineering is also about intelligent redistribution. The smartest engineers understand that removing mass in the right places unlocks performance gains that no amount of raw power can deliver on its own.

Lighter structures accelerate faster, consume less energy, and respond with greater precision. They achieve more by carrying less.

Why Does Weight Matter So Much in Performance Engineering?

-

Weight and Energy

The relationship between mass and motion is governed by immutable physics. Heavier objects demand exponentially more energy to move, stop, and change direction. Whether you’re launching a racing drone, accelerating an electric motor, or powering a vehicle around a circuit, excess weight drains energy and limits what’s achievable.

Efficiency in engineering starts with understanding this fundamental truth. Lower mass means reduced inertia and drag, which translates directly into extended range for drones, improved lap times for vehicles, and longer operational life for motors.

Weight reduction doesn’t just improve performance in isolation. It fundamentally changes what a system can achieve on the same energy budget, making it a cornerstone of sustainable design and carbon footprint reduction.

-

The Power-to-Weight Ratio

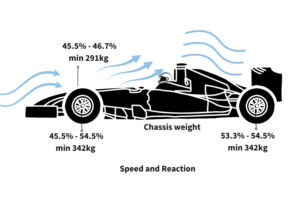

The power-to-weight ratio determines how quickly something accelerates, how precisely it responds, and how efficiently it operates under load. In motorsport, even marginal improvements in this ratio transform handling characteristics and braking performance.

Research demonstrates that reducing vehicle weight delivers measurable gains in control, stability, and competitive advantage.

This ratio matters universally across performance applications. A lighter composite motor sleeve allows for faster acceleration without demanding a more powerful motor.

Carbon fibre sports equipment lets athletes generate more speed with less effort. Advanced lightweight materials in drone construction extend flight time whilst improving manoeuvrability.

The equation remains elegantly simple: less weight, more performance.

-

Precision, Agility and Control

Lighter systems don’t merely move faster. They respond more predictably to inputs.

Lower inertia results directly into quicker reaction times, smoother stability, and significantly reduced vibration.

For high-speed drones navigating complex flight paths, this requires sharper turns and better camera stability. For athletes wielding carbon fibre tubes in sports equipment, it results in reduced fatigue and enhanced control over extended competition periods.

What Materials and Technologies Make Weight Reduction Possible Today?

Modern weight reduction relies on breakthroughs in material science innovation and intelligent design methodologies.

The tools available to engineers today represent a quantum leap from even a decade ago.

Carbon Fibre Composites

Carbon fibre delivers a strength-to-weight ratio that makes it the gold standard for performance applications. Its exceptional stiffness, combined with minimal mass, makes it ideal for composite motor sleeves, drone airframes, and sports equipment where every gram impacts performance.

The material’s directional properties allow engineers to place reinforcement exactly where loads occur, eliminating unnecessary weight elsewhere.

ACE specialises in carbon fibre tubes and non-conductive composite tubes engineered for demanding applications.

Our carbon tubes serve industries from motorsport to renewable energy, where weight savings directly translate to performance gains. As a carbon fibre tubes UK manufacturer, we’ve refined production techniques that deliver consistency and precision across high-volume runs.

Magnesium and Titanium Alloys

Whilst composites dominate many applications, lightweight metals retain crucial roles in performance engineering. Magnesium alloys offer excellent machinability combined with thermal properties that suit automotive and aerospace applications.

Their density, roughly two-thirds that of aluminium, makes them attractive for structural components where metal characteristics are non-negotiable.

Titanium provides unmatched strength in high-temperature environments and corrosive conditions.

Though more expensive, its performance in extreme applications justifies the investment. The key lies in understanding when to deploy each material and how to combine them intelligently with composites for hybrid solutions.

Hybrid and Recycled Composites

ACE’s work with recycled carbon fibre UK solutions proves that high performance doesn’t require high environmental impact. These materials maintain impressive structural performance whilst supporting circular design principles and reducing carbon footprint.

Recycled carbon fibre performance comparison studies show that properly processed materials can achieve 90-95% of virgin fibre properties in many applications.

This makes them viable for applications where absolute peak performance can trade slightly for sustainability gains. It’s engineering that considers lifecycle impact alongside immediate performance requirements.

Where Is Weight Reduction Transforming Different Industries?

-

Lightweight Engineering Impact Sports Performance

Carbon fibre sports equipment has fundamentally transformed competitive athletics. Cycling frames, rowing shells, tennis rackets, and golf clubs built from lightweight composites allow athletes to generate more speed with less energy expenditure.

The performance advantages are measurable and significant: faster sprint times, improved endurance, and reduced injury risk from repetitive strain.

-

Redefine Drone and Motor Performance

Drone airframe composites have revolutionised both commercial and recreational aviation. Lighter frames extend flight time, increase payload capacity, and improve manoeuvrability.

For inspection drones servicing infrastructure, longer flight time means covering more ground per battery charge, reducing operational costs. For racing or defence drones, reduced mass means sharper turns and explosive acceleration out of corners.

Lightweight composite solutions for drones address multiple performance parameters simultaneously.

Beyond simple weight reduction, carbon fibre provides vibration damping that improves camera stability and electronic reliability. Its electromagnetic transparency allows radio signals to pass unimpeded, unlike metal alternatives.

-

Lightweight Materials Used in Automotive and Aerospace

Motorsport and aviation have always pushed the boundaries of lightweighting. Carbon fibre body panels, magnesium alloy components, and hybrid composite structures reduce structural weight whilst maintaining rigorous safety standards.

Every kilogram removed lowers emissions, improves fuel efficiency, and enhances handling characteristics that define vehicle performance.

How Can You Work with a Specialist to Achieve Weight Reduction?

-

Define the Goal

Every project starts with clarity about objectives.

- Are you targeting longer endurance?

- Faster acceleration?

- Energy savings?

- Sustainability improvements?

How to improve the strength-to-weight ratio depends entirely on which performance parameters matter most for your application.

Drones optimising for battery life require different solutions than motors prioritising rapid response. Sports equipment balancing weight against durability needs different material strategies than automotive components.

Clear objectives guide material selection and design choices, ensuring effort focuses on parameters that matter most.

-

Select the Right Material

Choosing between carbon fibre, titanium, recycled composites, or hybrid solutions depends on application requirements, environmental conditions, and budget constraints.

ACE’s material selection expertise helps clients navigate these trade-offs intelligently.

Carbon fibre tubes offer exceptional performance for applications where stiffness and weight are paramount. Our ability to tailor custom carbon sleeves means clients get precisely the properties their application demands, without paying for characteristics they don’t need.

-

Prototype and Test

Weight reduction is inherently iterative. Prototypes undergo rigorous testing for stiffness, vibration control, thermal performance, and structural integrity under real-world conditions.

This reveals how theoretical designs perform in practice and where refinements are needed.

ACE’s in-house prototyping facilities allow rapid development cycles. We can test concepts, gather performance data, and refine designs before committing to production tooling.

This iterative approach reduces risk and accelerates time to market for lightweight solutions.

-

Move from Prototype to Production

Scaling composite manufacturing presents challenges around precision, repeatability, and quality control.

Production processes must maintain the tight tolerances that prototypes achieved whilst delivering consistent results across thousands of units.

ACE’s production systems for carbon fibre tubes and high-speed motor sleeves maintain rigorous quality standards.

Our processes ensure that production components match prototype performance, giving clients confidence that their designs will perform as intended at scale.

-

Continuous Improvement and Support

Performance engineering doesn’t end at delivery. Post-production refinement based on real-world performance data drives continuous improvement. Monitoring how components perform in service reveals opportunities for further optimisation in subsequent generations.

ACE’s commitment to sustainable innovation through recycled carbon fibre demonstrates this ongoing refinement.

We continuously improve our processes and materials, helping clients stay ahead of evolving performance requirements and sustainability expectations.

The Benefits of Working with a Specialist Like ACE

Advanced Composite Engineering brings decades of expertise in lightweight composite solutions. We understand that weight reduction is never just about making something lighter. It’s about making it demonstrably better across the performance parameters that matter most.

Our clients benefit from bespoke solutions designed specifically for sports, drones, motors, and demanding industrial applications. We provide technical guidance from initial concept through to full-scale manufacture, ensuring designs are both ambitious and achievable within budget and timeline constraints.

Sustainability sits at the heart of our innovation approach. Through ACE recycled carbon fibre and circular design principles, we help clients achieve performance goals whilst reducing environmental impact. This forward-thinking approach ensures solutions remain viable as sustainability regulations tighten.

ACE composites UK represents more than components. We’re a partner in performance optimisation, bringing material expertise, manufacturing capability, and problem-solving experience to every project. Every gram matters. Let ACE help you engineer your next breakthrough.

Ready to Engineer Lighter, Smarter, Stronger?

Whether you’re developing the next generation of sports equipment, designing more efficient drones, or optimising motor performance, ACE can help you unlock the advantages of intelligent weight reduction.

Call our composite specialists on 01670 335490 to discuss your next project. Our team brings practical experience across diverse applications and can guide you through material selection, design optimisation, and manufacturing strategies that deliver results.

Request a quote for custom carbon fibre tubes or sleeves tailored to your specific requirements. We work with businesses of all sizes, from startups developing breakthrough products to established manufacturers seeking performance improvements.

Download our composite glossary to understand your material options and the technical terminology that defines modern lightweight engineering. Knowledge empowers better decisions at every stage of development.

Contact ACE today and discover what’s possible when every gram serves a purpose.

Frequently Asked Questions

1. What is the benefit of weight reduction in engineering?

Reduced mass delivers higher efficiency, faster acceleration, and significantly lower energy demand across applications. Lighter structures require less power to operate, extend operational range, and respond more quickly to control inputs. These benefits compound in systems where weight savings improve multiple performance parameters simultaneously.

2. How does weight reduction improve motor performance?

Lightweight composite sleeves reduce rotational inertia, which allows motors to accelerate faster and respond more precisely to control signals. Lower mass also reduces heat buildup and vibration, extending component lifespan whilst improving overall efficiency. The result is motors that perform better whilst lasting longer under demanding conditions.

3. Which materials provide the best strength-to-weight ratio?

Carbon fibre composites lead the field, offering exceptional stiffness at minimal weight. The material’s directional properties allow engineers to optimise fibre orientation for specific load cases. Magnesium and titanium alloys provide excellent alternatives for applications requiring metallic properties, whilst hybrid materials combine the advantages of multiple material systems.

4. What are composite motor sleeves, and how do they work?

These cylindrical components fit around motor rotors to provide stability and protection. They offer high stiffness and thermal insulation at significantly lower weight than traditional metal alternatives. By reducing rotational mass, they allow motors to accelerate faster, whilst the composite material’s vibration-damping properties improve reliability and extend operational life.

5. What are the challenges of lightweight design?

Engineers must balance multiple competing requirements: lightness against strength, performance against cost, advanced materials against manufacturability, and short-term performance against long-term recyclability. Success requires understanding which trade-offs are acceptable for specific applications and which performance parameters cannot be compromised.