The world of sport has never been more competitive. Athletes are pushing the boundaries of human performance, shaving milliseconds off personal bests and achieving feats that would have seemed impossible just decades ago. Behind these remarkable achievements lies a quiet revolution in material science and engineering technology.

Today’s elite athletes demand equipment that meets their needs and also enhances their capabilities. They need gear that’s lighter without being fragile, stronger without adding bulk, and more responsive without sacrificing safety.

Traditional materials like steel, aluminium, and wood, whilst reliable, simply can’t deliver the sophisticated performance characteristics that modern sport demands.

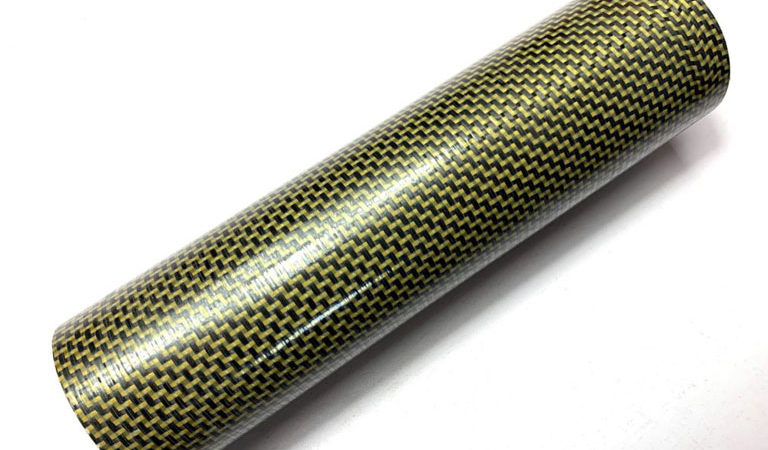

This is where composites and carbon tubes shine as game-changers. These advanced materials are transforming everything from cycling frames to tennis rackets, from rowing shells to ski poles. They’re redefining what’s possible in sports equipment design.

This results in athletes being able to perform better, safer, and longer than ever before.

Why Composites Are Shaping the Future of Sports Gear

The composite revolution didn’t begin in sport; it started in the high-stakes worlds of aviation, marine engineering, and Formula One, where performance and safety are paramount.

These industries pioneered the use of advanced materials because traditional options like steel and aluminium simply couldn’t deliver the performance required for cutting-edge applications.

Now, this technology has found its way into the sports world, and the benefits are remarkable. Composites offer three key advantages that are transforming athletic performance:

Key Advantages of Composite Materials

- Lightweight construction that doesn’t compromise on strength, allowing athletes to move faster and with greater endurance

- Exceptional durability that withstands the rigours of elite competition whilst maintaining performance characteristics over time

- Tailorable properties that can be engineered to meet the specific demands of different sports and playing styles

Ways Carbon Tubes Improve Next-Gen Sports Equipment

Carbon tubes represent the pinnacle of this composite evolution, offering the perfect blend of strength, lightness, and design flexibility that’s pushing sports performance to new heights.

1. Lightweight Strength Revolution

When comparing carbon tubes to traditional materials like aluminium, steel, and wood, the differences are striking. A carbon fibre bicycle frame, for instance, can be up to 40% lighter than its aluminium equivalent whilst maintaining superior strength and stiffness. This isn’t just about numbers on a scale, as it translates directly into real-world performance advantages.

-

Cycling Applications

In cycling, lighter frames mean better climbing efficiency. When you’re grinding up Box Hill or tackling the Pennines, every gram matters. Professional cyclists know that a lighter bike doesn’t just make climbs easier; it improves acceleration, reduces fatigue, and allows for more responsive handling throughout a race.

-

Rowing Performance

Rowing provides another compelling example. Carbon fibre shells are significantly lighter than traditional wooden boats, creating less drag through the water whilst maintaining the structural integrity needed to handle the powerful forces generated by elite rowers. The result? Faster times on the water and improved efficiency with each stroke.

-

Skiing Excellence

In skiing, carbon fibre poles offer the perfect combination of lightweight construction and shock absorption. They resist snapping under the extreme forces of high-speed descents whilst absorbing vibrations that would otherwise travel up through an athlete’s arms and shoulders.

2. Understanding Strength-to-Weight Ratio

This crucial metric measures how much strength a material provides relative to its weight. Carbon tubes excel here, offering strength-to-weight ratios that can be up to five times better than steel and significantly superior to aluminium.

3. Stiffness, Energy Transfer & Vibration Control

Stiffness might sound like a drawback, but in sports equipment, it’s often the key to maximising performance. Proper stiffness ensures that energy from an athlete’s movements is efficiently transferred to the ball, water, or ground rather than being absorbed by the equipment itself.

-

Tennis Equipment Innovation

Consider tennis rackets, where modern carbon fibre designs allow engineers to precisely control stiffness in different areas of the frame. The result is better power transfer during shots whilst simultaneously providing vibration damping that reduces the jarring impact felt by players. This combination results in more powerful, controlled shots with a reduced risk of tennis elbow and other repetitive strain injuries.

-

Golf Club Technology

Golf clubs showcase another dimension of this technology. Carbon fibre shafts can be engineered with specific flex characteristics that match a golfer’s swing speed and style. The material’s ability to absorb vibrations means less strain on wrists and elbows, whilst its stiffness properties ensure maximum energy transfer to the ball for greater distance and accuracy.

4. Customisation and Design Flexibility

One of carbon fibre’s greatest strengths lies in its moldability during manufacture. Unlike metals, which are cast or machined into shape, carbon fibre can be laid up in complex moulds to create aerodynamic frames and ergonomic shapes that would be impossible or prohibitively expensive to achieve with traditional materials.

This flexibility aids directly into performance benefits:

- Cycling frames can be shaped to slice through the air more efficiently, with tubes that are wide where aerodynamic efficiency matters most and narrow where weight reduction is the priority

- Integration of components can be seamless, eliminating the drag-creating joints and welds found in traditional frame construction

- Frame geometries can better accommodate different body types and riding styles, improving biomechanical efficiency

The Rise of Nanotube Composites

Carbon nanotubes (CNTs) represent the cutting edge of materials science—imagine carbon fibres shrunk down to the molecular level, then engineered to be stronger than any material we’ve previously known. When incorporated into composite materials, they create what many consider to be the ultimate sports equipment material.

Benefits of Nanotube Composites

- Ultra-high strength-to-weight ratio that exceeds even traditional carbon fibre by significant margins

- Exceptional fatigue resistance that maintains performance characteristics even after millions of loading cycles

- Advanced vibration absorption that provides superior comfort and reduces the risk of repetitive strain injuries

Performance and Safety Benefits for Athletes

The performance benefits of carbon tubes extend far beyond simple weight savings. Lighter equipment reduces fatigue, allowing athletes to maintain peak performance for longer periods.

When you’re carrying less weight, whether it’s a tennis racket, cycling frame, or rowing oar, you can focus more energy on technique and power generation rather than simply managing the equipment.

Safety Advantages

Safety represents another crucial advantage, particularly in high-impact and contact sports. Carbon nanotube-reinforced protective shells, helmets, and guards can absorb and dissipate impact energy more effectively than traditional materials whilst remaining lighter and more comfortable to wear.

The vibration absorption properties of advanced carbon composites also play a significant role in injury prevention.

By reducing the harsh vibrations transmitted through equipment, carbon tubes help minimise joint stress and reduce the risk of repetitive strain injuries that can end athletic careers.

Carbon Tubes vs Traditional Materials Comparison

| Property | Carbon Tubes | Aluminium | Wood | Steel |

| Strength-to-weight ratio | Excellent | Good | Poor | Fair |

| Durability | High | Medium | Low | High |

| Vibration absorption | High | Low | Medium | Low |

| Customisability | Very High | Medium | Low | Low |

| Design flexibility | Excellent | Good | Limited | Limited |

| Fatigue resistance | Excellent | Good | Poor | Excellent |

In Summary

Carbon tubes represent a genuine game-changer in sports equipment design, offering unmatched combinations of speed, strength, durability, and safety. As we look towards the future, carbon nanotube composites promise to push these boundaries even further, creating possibilities that seemed like science fiction just a few years ago.

For athletes serious about performance, equipment manufacturers seeking a competitive advantage, and innovative companies looking to push the boundaries of what’s possible, carbon tubes offer a clear path forward. The technology is proven, the benefits are real, and the potential for future development is enormous.

Why Work With Advanced Composite Engineering?

Advanced Composite Engineering (ACE) has built a reputation as a leading designer and manufacturer of composite tubes, with expertise that spans sports, aerospace, marine, and automotive applications.

This cross-industry experience brings unique insights to sports equipment development, applying lessons learned from the most demanding applications to create superior sporting solutions.

Based in the UK, ACE combines local credibility with world-class engineering knowledge. Our understanding of both the technical demands of high-performance sports equipment and the practical requirements of manufacturing means we can guide projects from initial concept through to production-ready solutions.

If you’re developing the next generation of cycling frames or exploring entirely new applications for carbon tubes in sport, ACE has the expertise and facilities to bring your vision to reality. Check out our comprehensive composite glossary, a helpful guide explaining everything from layups and resin types to tolerances and finish options.

Complete our product enquiry form to get a tailored quote for your carbon fibre tubes and carbon sleeves to suit your sports needs. Just tell us your specs, and we’ll do the rest.

Get in touch with our composite specialists today. We’re happy to help with tube sizing, tooling lead times, minimum order quantities, and technical queries.

Frequently Asked Questions

1. Are carbon fibre tubes better than aluminium in sports equipment?

Yes, carbon fibre tubes generally outperform aluminium in sports applications. They offer superior strength-to-weight ratios, better vibration damping, and greater design flexibility. Whilst aluminium remains more affordable, carbon fibre provides performance advantages that are particularly valuable in competitive sports where marginal gains matter.

2. Are carbon tubes safe for high-impact sports?

Absolutely. Carbon tubes, particularly those incorporating nanotube technology, excel at absorbing and dissipating impact energy. They’re increasingly used in protective equipment like helmets and guards because they can provide superior protection whilst remaining lighter and more comfortable than traditional materials.

3. Is carbon fibre recyclable in the sports industry?

Carbon fibre recycling is an evolving area with significant progress being made. Whilst traditional recycling methods have been challenging, new technologies are emerging that can recover carbon fibres for reuse in new applications. Many manufacturers are also exploring bio-based resins and more sustainable production methods to reduce environmental impact.

4. Are carbon tubes safe and comfortable for athletes?

Yes, carbon tubes actually enhance athlete safety and comfort. Their excellent vibration-damping properties reduce joint stress and fatigue, whilst their lightweight nature reduces the physical burden on athletes. The ability to customise stiffness and flex characteristics also means equipment can be tailored to individual athletes’ needs and biomechanics.

5. How long does carbon fibre sports equipment typically last?

High-quality carbon fibre sports equipment is exceptionally durable and can last many years with proper care. The material’s excellent fatigue resistance means it maintains its performance characteristics even after extensive use.

Professional-grade carbon fibre equipment often outlasts aluminium alternatives, making it a sound long-term investment despite the higher initial cost.