When you’ve just launched your drone for what should be a routine aerial photography session. Within minutes, you notice something’s wrong. The footage could be shaky despite perfect weather conditions, the flight time might be disappointingly short, and worse still, you can hear an ominous rattling sound. Your drone struggles back to the landing pad, and upon inspection, you discover stress fractures in the airframe arms.

These are signs that point towards an inadequate airframe material that simply can’t handle the demands of modern drone operations.

The airframe is quite literally the backbone of your drone, the structural foundation that holds everything together. Making a mistake in this, and no amount of advanced electronics, powerful motors, or sophisticated software can compensate for the fundamental weakness at the heart of your aircraft.

Let us explore why carbon tubes have become the gold standard for professional drone airframes, covering everything from the basic science behind composite materials to real-world performance benefits that could revolutionise your drone’s capabilities.

What is a Drone Airframe?

Before diving into the world of carbon fibre tubes, it’s essential to understand exactly what we mean by a drone airframe and why it’s so critical to your aircraft’s performance.

Think of a drone airframe as the skeleton of the aircraft; it’s the structural framework that holds all other components in their correct positions. Just as your skeleton provides the framework for your muscles, organs, and systems to function properly, the airframe ensures that motors, propellers, flight controllers, cameras, and batteries all maintain their optimal relationships during flight.

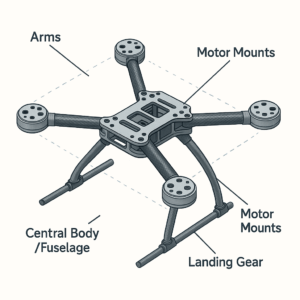

Key Components of a Drone Airframe

A typical drone airframe consists of several elements:

- Arms: These extend from the central body to hold the motors and propellers. They must be strong enough to handle the thrust forces and vibrations from spinning motors while remaining lightweight enough not to drain battery life.

- Central Body/Fuselage: The main hub that houses the flight controller, battery, and often the gimbal and camera systems. This section experiences complex stress patterns as forces from all four (or more) arms converge.

- Landing Gear: The structural elements that absorb landing impacts and provide ground clearance for delicate components.

- Motor Mounts: Critical attachment points that must precisely maintain motor alignment while withstanding constant vibration and thrust forces.

Essential Properties for Airframe Success

For an airframe to perform effectively, it must excel in several key areas:

- Structural Rigidity: The airframe must resist bending and twisting forces that could misalign motors or create unwanted vibrations. Even small deflections can cause significant control problems and reduce flight efficiency.

- Weight Minimisation: Every gram saved in the airframe translates directly to longer flight times, higher payload capacity, or both. This is where material choice becomes crucial.

- Vibration Damping: Modern drones carry sensitive electronics and cameras that suffer from vibration. The airframe must absorb and dampen vibrations rather than amplify them.

- Durability Under Stress: From takeoff thrust to landing impacts, wind gusts to emergency manoeuvres, the airframe must maintain its integrity under varying loads and environmental conditions.

- Repairability: Professional applications demand airframes that can be easily maintained and repaired when necessary, minimising downtime and operational costs.

What Are Composite Materials?

Composite materials represent a fundamental shift in engineering thinking. Rather than relying on a single material to meet all requirements, composites combine different materials to create something superior to any individual component.

At its core, a composite consists of two main elements:

- The Matrix: Usually a resin (commonly epoxy) that binds everything together and transfers loads between fibres. The matrix also protects the fibres from environmental damage and provides the finished shape.

- The Reinforcement: High-strength fibres (in our case, carbon fibres) that provide the primary structural strength and stiffness.

Carbon fibres themselves are remarkable materials, thin strands of crystalline carbon, each about 5-7 micrometres in diameter (thinner than human hair), with strength characteristics that can exceed steel while weighing a fraction as much.

How Carbon Tubes Are Made?

Carbon tubes for drone applications are typically manufactured using a process called “roll wrapping” or “mandrel wrapping.” This technique, refined over decades in industries like aerospace and defence, allows for precise control over fibre placement and wall thickness.

Here’s how it works:

- Preparation: Pre-impregnated carbon fibre sheets (called “prepreg”) are cut to specific sizes and angles.

- Wrapping: These sheets are carefully wrapped around a precision mandrel (forming tool) in predetermined orientations. The fibre direction can be controlled to optimise strength in specific directions.

- Consolidation: The wrapped assembly is compressed to remove air bubbles and ensure proper fibre-to-resin ratios.

- Curing: Heat and pressure cure the resin, creating strong chemical bonds that lock the structure in place.

- Finishing: The mandrel is removed, and the tube is trimmed and finished to precise tolerances.

What is the Science Behind Carbon Fibre Performance

- Specific Strength: This critical measurement divides material strength by its weight. Carbon composites excel here because they can be stronger than steel while weighing 80% less.

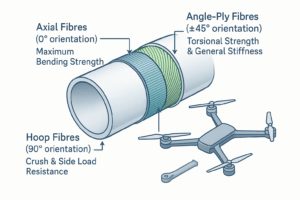

- Fibre Alignment: The direction fibres point within the composite. Axial fibres (running along the tube length) provide bending strength, while hoop fibres (wrapped around the circumference) resist internal pressure and crushing forces.

- Modulus of Elasticity: This measures how much a material deflects under load. Carbon fibres have an extremely high modulus, meaning they resist bending and stretching exceptionally well.

- Coefficient of Thermal Expansion (CTE): This describes how much a material expands when heated. Carbon fibres actually have a slightly negative CTE, meaning they can contract slightly when heated, a unique property that helps maintain precision in varying temperatures.

- Fatigue Resistance: The ability to withstand repeated loading cycles without failure. Unlike metals, which can develop fatigue cracks over time, properly designed carbon composites can handle millions of load cycles without degradation.

Why Carbon Tubes Are Ideal for Drone Airframes

Now we reach the heart of the matter: why carbon tubes have become the material of choice for serious drone applications.

1. Exceptional Strength-to-Weight Ratio

The single most compelling advantage of carbon tubes is their extraordinary strength-to-weight ratio, often called “specific strength.”

Consider these numbers: carbon fibre tubes can be approximately 5 times lighter than steel and nearly 2 times lighter than aluminium, while maintaining comparable or superior strength characteristics. For drone applications, this translates directly into tangible benefits:

- Extended Flight Time: Every gram saved in airframe weight can be redirected to battery capacity. A 200-gram weight saving might add 2-3 minutes of flight time, crucial for professional applications where mission duration matters.

- Increased Payload Capacity: Lighter airframes mean more capacity for cameras, sensors, or other mission-critical equipment without compromising flight performance.

- Improved Efficiency: Less structural weight means less energy required to maintain flight, improving overall system efficiency and reducing operational costs.

2. Superior Rigidity and Structural Stiffness

Rigidity: the resistance to deformation under load, is where carbon tubes truly shine. The high modulus of elasticity of carbon fibres means that carbon tube airframes maintain their shape precisely under the varying loads of flight.

This matters more than you might initially think:

- Motor Alignment: Even small deflections in airframe arms can cause motors to point in slightly different directions, creating control problems and reducing efficiency. Carbon tubes maintain precise geometry under load.

- Reduced Control System Load: When the airframe doesn’t flex, the flight controller doesn’t need to constantly compensate for structural movement, resulting in more precise control and reduced battery drain.

- Consistent Performance: A rigid airframe performs the same way regardless of payload, weather conditions, or flight manoeuvres, making the aircraft more predictable and easier to operate.

3. Vibration Damping and Fatigue Resistance

One of carbon fibre’s most valuable but often overlooked properties is its ability to dampen vibrations while resisting fatigue.

Traditional materials like aluminium can amplify certain vibrations, creating resonance problems that plague drone operators. Carbon composites, however, have inherent damping properties that absorb vibration energy rather than transmitting it.

Reduced vibration transmission means cleaner footage and photography, even without expensive gimbal systems.

Sensitive components like GPS modules, IMUs, and flight controllers perform better when isolated from motor vibrations.

While aluminium components may develop stress cracks after thousands of flight cycles, carbon tubes can handle millions of load reversals without degradation.

4. Outstanding Environmental Resistance

Professional drones operate in challenging environments, from coastal areas with salt spray to industrial sites with chemical exposure. Carbon composites excel in these conditions:

Unlike aluminium, which can corrode in marine environments, carbon tubes are virtually immune to environmental degradation.

Most chemicals that would attack metal components do not affect properly formulated carbon composites.

5. Thermal Stability

Temperature variations can wreak havoc on drone precision, but carbon tubes offer remarkable thermal stability. The near-zero coefficient of thermal expansion means carbon tubes maintain their dimensions across wide temperature ranges.

Carbon fibres can actually conduct heat away from motors and electronics, helping manage thermal loads.

Whether operating in Arctic conditions or desert heat, carbon tube airframes maintain their structural properties.

6. Design Flexibility

Carbon tube manufacturing techniques offer unprecedented design flexibility. Unlike machined metal parts, carbon tubes can be manufactured in complex shapes, tapered profiles, and varying wall thicknesses to optimise performance.

Mounting points, reinforcement areas, and even threaded inserts can be built into the composite structure during manufacturing.

Modern composite manufacturing can produce custom prototypes quickly, allowing for iterative design improvements.

In Comparison: Carbon Tubes vs Alternative Materials

To fully appreciate carbon tubes’ advantages, let’s examine how they compare to other common airframe materials:

| Property | Carbon Tubes | Aluminium | Plastics/Fibreglass |

| Weight | Lightest (baseline) | 2x heavier | Variable, often heavier for equivalent strength |

| Strength | Excellent tensile and flexural strength | Good strength, but prone to fatigue | Lower strength, more flexible |

| Stiffness | Extremely high modulus | Moderate stiffness | Low to moderate stiffness |

| Vibration Damping | Excellent natural damping | The poor can amplify vibrations | Moderate damping |

| Corrosion Resistance | Excellent, virtually immune | Poor, requires coating/treatment | Good to excellent, depending on type |

| Fatigue Life | Millions of cycles without degradation | Limited, cracks develop over time | Variable, often poor |

| Temperature Stability | Excellent, minimal expansion | Moderate expansion with temperature | Can be poor, especially plastics |

| Repairability | Requires specialist techniques, but it is possible | Easy to machine and repair | Variable, some are easily repairable |

| Initial Cost | Higher upfront investment | Moderate cost | Lowest initial cost |

| Long-term Value | Excellent due to longevity | Moderate due to replacement needs | Poor to moderate |

How to Choose Carbon Tubes for Your Drone Airframe

Selecting the right carbon tubes for your specific application requires understanding several key factors:

1. Diameter and Wall Thickness Considerations

Larger Diameters: Provide higher bending stiffness for the same weight, but may be overkill for smaller drones and can create ground clearance issues.

Wall Thickness: Thicker walls increase strength and stiffness but add weight. The optimal thickness depends on your specific load requirements and weight budget.

General Guidelines:

- Racing drones: Smaller diameter (8-12mm), thin walls for minimum weight

- Photography platforms: Medium diameter (15-20mm), moderate walls for vibration control

- Heavy-lift industrial: Large diameter (25mm+), thicker walls for maximum strength

2. Fibre Orientation and Layup

The way carbon fibres are oriented within the tube wall dramatically affects performance

Axial Fibres (0° orientation): Provide maximum bending strength along the tube length. Essential for drone arms that must resist motor thrust loads.

Hoop Fibres (90° orientation): Resist crushing and internal pressure. Important for tubes that will be clamped or experience side loads.

Angle-Ply Fibres (±45°): Provide torsional strength and general stiffness. Useful for reducing weight while maintaining adequate strength.

Most high-performance drone tubes use a combination of orientations, typically:

- 60-70% axial fibres for bending strength

- 15-20% hoop fibres for crush resistance

- 15-20% angle-ply fibres for torsional stiffness

3. Resin System Selection

- Epoxy Resins: The gold standard for structural applications, offering excellent strength, environmental resistance, and fatigue life. More expensive but worth it for professional use.

- Vinyl Ester: Good chemical resistance, often used in marine applications. Moderate cost and performance.

- Polyester: Lowest cost option, but with limited performance and environmental resistance.

For drone applications, epoxy resin systems are generally recommended despite their higher cost.

4. Quality and Manufacturing Standards

Not all carbon tubes are created equal. Key quality indicators include:

- Tolerances: High-quality tubes maintain tight tolerances on diameter, wall thickness, and straightness.

- Consistency: Professional manufacturers maintain consistent fibre content, void levels, and surface finish.

- Certifications: Look for suppliers with relevant quality certifications (ISO 9001:2015) and aerospace experience.

- Testing: Reputable suppliers provide material certificates and can offer custom testing if required.

Practical Applications of Carbon Tubes

Carbon tube airframes have proven themselves across diverse drone applications:

Professional Photography and Cinematography

High-end camera drones inspire a series of uses of carbon fibre extensively. The benefits are immediately apparent:

- Vibration Isolation: Carbon’s natural damping properties provide smoother footage than metal alternatives

- Payload Efficiency: Weight savings allow for larger cameras and longer flight times

- Durability: Professional operators report fewer maintenance issues and longer service life

Industrial Inspection Drones

Companies using drones for infrastructure inspection, particularly in challenging environments, have found carbon airframes essential:

- Chemical Resistance: Offshore oil platform inspections expose drones to salt spray and hydrocarbon vapours

- Temperature Stability: Power line inspections in desert conditions require materials that maintain precision across temperature extremes

- Fatigue Life: Daily operation cycles demand components that won’t fail unexpectedly

Racing and Competition

The drone racing community has embraced carbon fibre for obvious reasons:

- Crash Resistance: Quality carbon frames often survive impacts that would destroy aluminium alternatives

- Responsiveness: Reduced flex means more precise control response

- Weight Savings: Every gram saved improves acceleration and manoeuvrability

Military and Defence Applications

While specific applications remain classified, defence contractors report significant advantages from carbon airframes:

- Stealth Properties: Carbon composites can be designed to minimise radar signature

- Reliability: Mission-critical applications demand materials that won’t fail

- Environmental Performance: Global deployment requires materials that perform consistently worldwide

Summary and Best Practices

Carbon fibre tubes represent a paradigm shift in drone airframe design, offering a combination of properties that simply cannot be matched by traditional materials. The key advantages, exceptional strength-to-weight ratio, vibration damping, environmental resistance, and fatigue life, directly address the primary challenges facing drone operators.

Key Takeaways

- Weight matters: Carbon tubes’ light weight translates directly to better flight performance

- Stiffness is crucial: Maintaining precise geometry under load improves control and efficiency

- Vibration kills performance: Carbon’s natural damping protects cameras and electronics

- Environment is everything: Corrosion resistance and thermal stability extend operational life

- Quality counts: Invest in properly manufactured tubes from experienced suppliers

Take Your Drone Airframe Further with Advanced Composite Engineering

At Advanced Composite Engineering (ACE), we specialise in carbon fibre tubes that deliver the strength, rigidity, and lightweight performance modern drone airframes demand. With over 40 years of experience serving aerospace, defence, and industrial sectors, we bring proven expertise to every project, from hobbyist builds to mission-critical UAVs.

Our UK-based team combines ISO 9001:2015 certified quality standards with advanced roll-wrap manufacturing techniques, ensuring every carbon tube meets the highest levels of precision, durability, and structural integrity.

If you need lightweight drone structure materials for extended flight time or custom carbon composite airframe solutions to handle demanding payloads, ACE can deliver.

Why Work With ACE?

- Bespoke engineering: Tubes tailored to your exact specifications, including diameter, wall thickness, fibre layup, and resin system.

- Cross-industry knowledge: Insights gained from aerospace and defence are applied directly to drone innovation.

- Comprehensive resources: Access our Composite Glossary to decode technical terms and make informed decisions.

- Trusted quality: Over four decades of delivering carbon fibre solutions that perform in the harshest environments.

Ready to Optimise Your Drone’s Airframe?

Complete our product enquiry form to receive a tailored quote for carbon fibre tubes and carbon sleeves that match your project’s needs. Call our composite specialists on 01670 335490 to discuss technical requirements, tube sizing, or application-specific guidance.

Explore our composite resources to better understand material options and how they can transform your drone’s performance.

Frequently Asked Questions

1. What makes carbon fibre tubes better than aluminium for drone airframes?

Carbon fibre offers a far higher strength-to-weight ratio compared to aluminium. While aluminium is durable, it is heavier and prone to fatigue cracks and corrosion. Carbon tubes reduce weight, extend flight times, and provide stiffness that maintains motor alignment, key for stable, efficient drone performance.

2. How do carbon tubes improve drone flight stability?

The rigidity of carbon composites minimises bending and twisting under load. This means motors stay perfectly aligned, reducing vibrations and control corrections. The result is a smoother, more predictable flight and cleaner aerial footage.

3. Why is vibration damping important in drone airframes?

Uncontrolled vibrations can blur footage and damage sensitive electronics. Carbon fibre naturally absorbs vibrations instead of amplifying them, protecting flight controllers, GPS units, and cameras while extending component lifespan.

4. Do square carbon tubes perform differently from round tubes?

Square carbon tubes offer superior torsional rigidity and distribute loads more evenly across joints. This makes assembly easier, improves shock absorption, and reduces the risk of fractures under heavy loads, particularly useful in racing drones or industrial drones carrying heavier payloads.

5. Are carbon fibre airframes weather-resistant?

Carbon composites are immune to corrosion, resistant to chemicals, and stable across extreme temperatures. Unlike metals that expand or corrode in humid or salty environments, carbon fibre airframes maintain integrity whether flying in desert heat, Arctic cold, or coastal conditions.